1����、 接頭的方法: 橡膠輸送帶接頭的方法有:機(jī)械接頭、冷粘接頭���、熱硫化接頭等幾個常用的方法�����。 機(jī)械接頭一般是指使用皮帶扣接頭����,這種接頭方法方便便捷,也比較經(jīng)濟(jì)�����,但是接頭的效率低��,容易損壞�,對橡膠輸送帶產(chǎn)品的使用壽命有一定影響。 PVC和PVG整芯阻燃抗靜電橡膠輸送帶接頭中��,一般8級帶以下的產(chǎn)品都采用這種接頭方法�����。

1. Joint method: Rubber conveyor belt joint method: mechanical joint, cold bonded joint, hot vulcanized joint and other commonly used methods. Mechanical joint generally refers to the use of belt buckle joint, which is convenient and economical, but the efficiency of the joint is low and easy to damage, which has a certain impact on the service life of rubber conveyor belt products. In the joints of PVC and PVG integral core flame retardant and antistatic rubber conveyor belts, the joint method is generally used for products below grade 8 belt.

2��、冷粘接頭:即采用冷粘粘合劑來進(jìn)行接頭����。這種接頭辦法比機(jī)械接頭的效率高,也比較經(jīng)濟(jì)���,應(yīng)該能夠有比較好的接頭效果,但是從實(shí)踐來看,由于工藝條件比較難掌握����,另外粘合劑的質(zhì)量對接頭的影響非常大,所以不是很穩(wěn)定�。 熱硫化接頭,實(shí)踐證明是理想的一種接頭方法��,能夠保證高的接頭效率��,同時也非常穩(wěn)定����,接頭壽命也很長,容易掌握���。但是存在工藝麻煩�����、費(fèi)用高��、接頭時間長等缺點(diǎn)�。

2. Cold bonded joints: that is to say, cold bonded adhesives are used for joints. This kind of joint method is more efficient and economical than mechanical joint. It should have better joint effect. However, in practice, it is not very stable because the process conditions are difficult to master and the quality of adhesives has a great influence on the joint. Thermal vulcanized joints have been proved to be the most ideal joint method, which can ensure high joint efficiency, stability, long service life and easy to grasp. However, there are some shortcomings, such as troublesome process, high cost and long joint time.

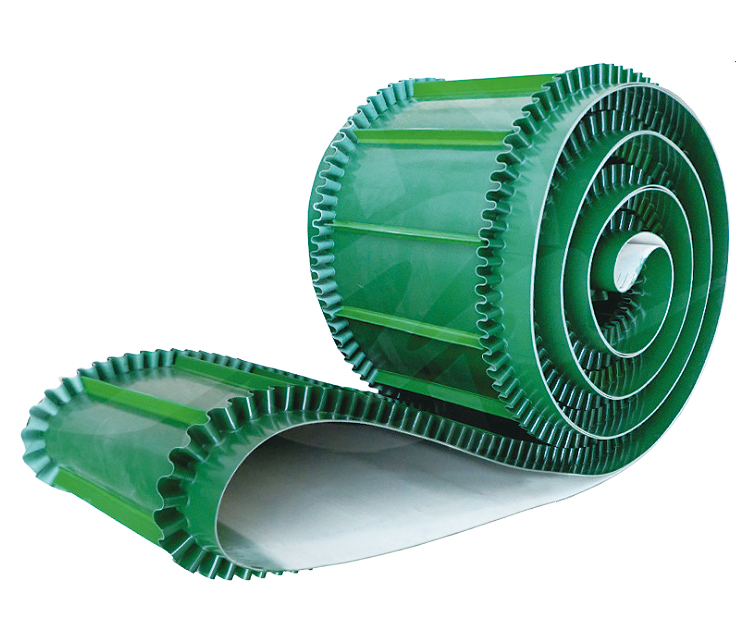

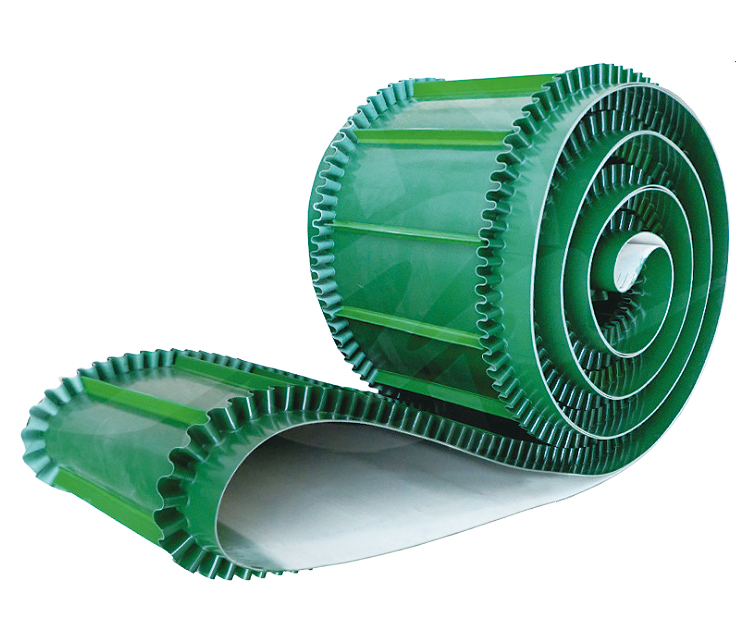

3�、分層橡膠輸送帶的接頭: 可以根據(jù)需要采用機(jī)械接頭�、冷粘接頭����、熱硫化接頭等接頭方法。一般冷粘接頭���、熱硫化接頭采取的是階梯式結(jié)構(gòu)接頭�����。

3. Joints of layered rubber conveyor belts: mechanical joints, cold-bonded joints and hot-vulcanized joints can be used as required. Generally, the cold bonded and hot vulcanized joints adopt the stepped structure joints.

4�、PVC和PVG整芯阻燃橡膠輸送帶的接頭: 由于整芯帶的結(jié)構(gòu)比較特殊�,接頭不太容易,所以大多數(shù)采用機(jī)械接頭辦法����,即皮帶扣接頭。但是8級以上的橡膠輸送帶�����,為了保證接頭效果�,一般還是采用熱硫化接頭的方法。接頭的結(jié)構(gòu)都是指狀接頭�����。PVC和PVG整芯阻燃橡膠輸送帶的熱硫化接頭工藝比較復(fù)雜����,對設(shè)備的要求也比較高。

4. Joints of PVC and PVG Whole-core flame-retardant rubber conveyor belts: Because the structure of the Whole-core belt is special and the joints are not easy, most of them adopt mechanical joints, i.e. belt buckle joints. However, for rubber conveyor belts above grade 8, in order to ensure the effect of joints, hot vulcanized joints are generally used. The joints are all finger joints. The process of hot vulcanization joint of PVC and PVG whole core flame retardant rubber conveyor belt is complex, and the requirement for equipment is relatively high.